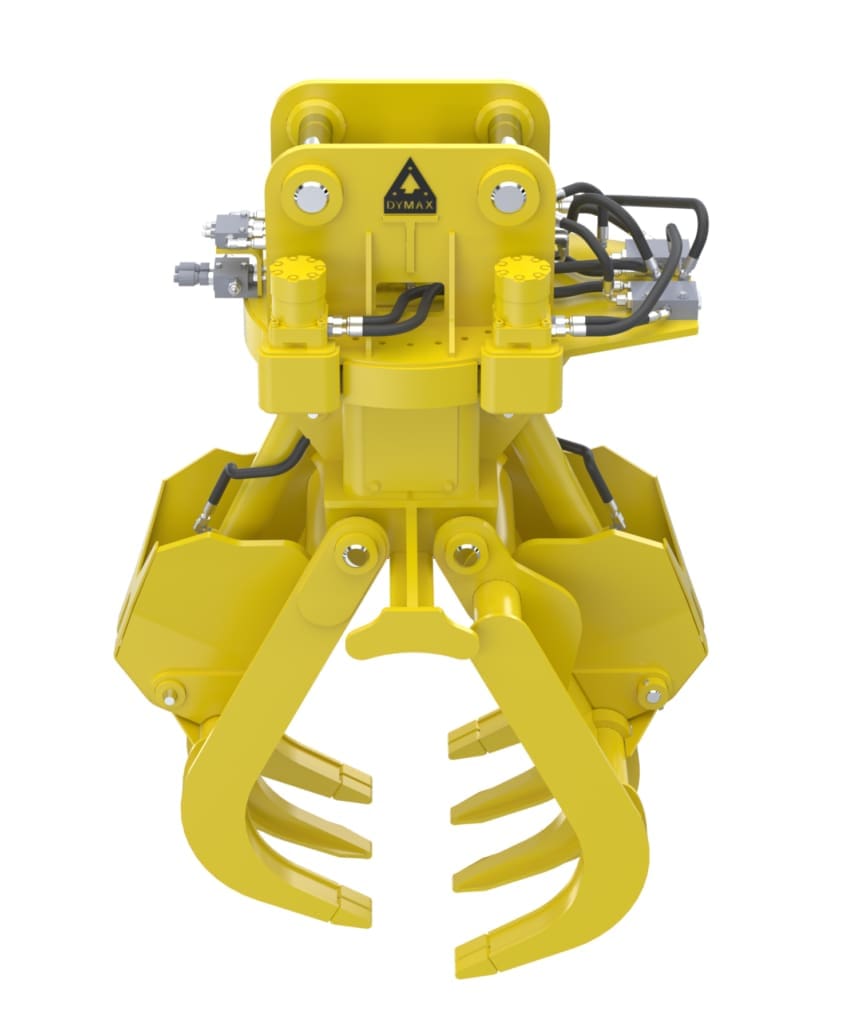

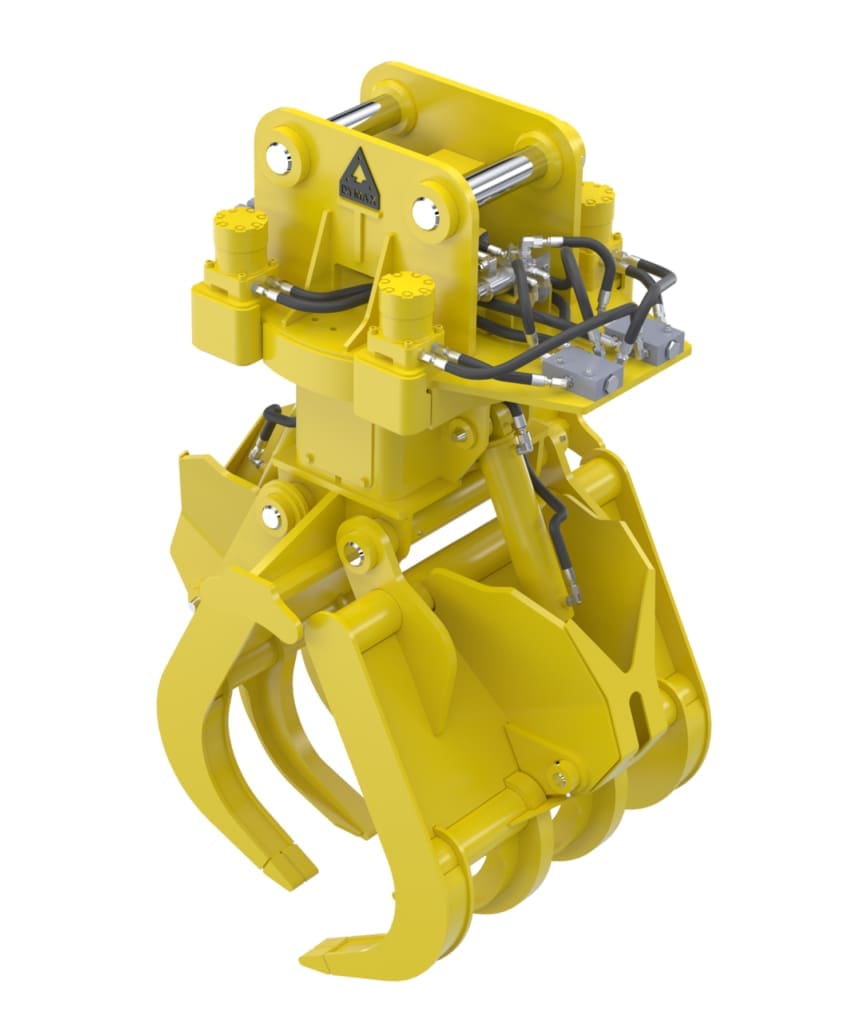

HEAVY DUTY FORESTRY GRAPPLE (360° ROTATION)

For Hydraulic Excavators

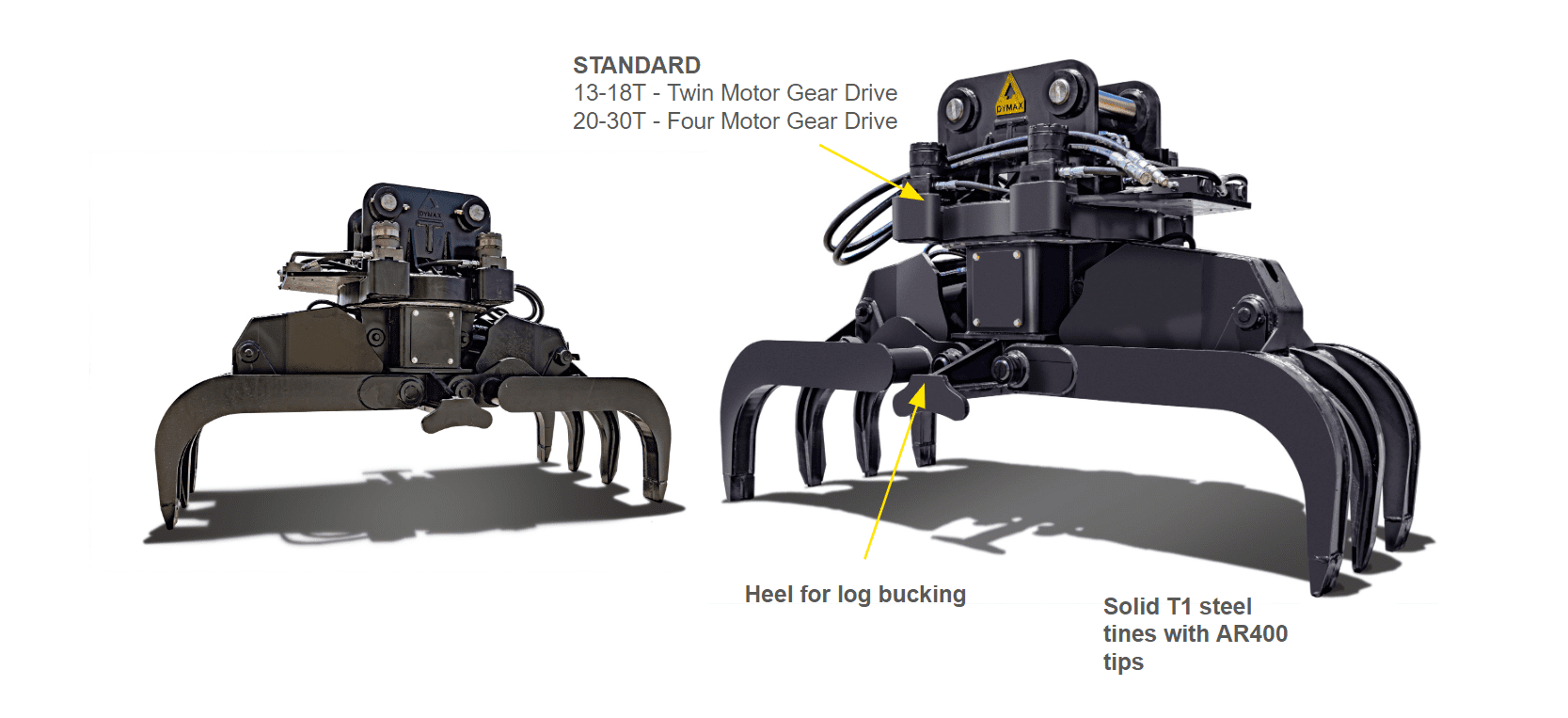

Dymax Forestry Grapples feature 360-degree rotation and are built tough for forestry and greenwaste handling, featuring durable T1 steel tines that grip with strength and precision. Designed with a heel for efficient bucking and sorting, it offers unmatched versatility and control in demanding applications. Whether you’re loading logs or clearing debris, this grapple is engineered to handle the job with reliability and rugged performance.

STANDARD FEATURES:

- 3 over 4 tine design

- TWO or FOUR rotation drive motors with pinion support and guard package (subject to size of machine)

- Side heel arms for log handling

- Built in cylinder covers

- Machine adapter with pins

OPTIONS:

- 24v electro hydraulic valve with wire, fuse and switch.

SPECIFICATIONS

| Model Code Description Weight |

| DX-GL-FYHD-360-HX-13T

Grapple-Forestry Heavy Duty-360 degrees rotation-Hydraulic Excavator-13 ton STANDARD FEATURES: 3 over 4 tine design, two rotation drive motors with pinion support and guard package, side heel arms for log handling, built in cylinder covers with 3.50 x 14.00 cylinders, machine adapter with pins 60-65mm, max tine opening between tips: 71 inches / 1.8m, material diameter (min rating): 5.25 inches / 13cm. Weight: 2850 lbs |

| DX-GL-FYHD-360-HX-20T

Grapple-Forestry Heavy Duty-360 degrees rotation-Hydraulic Excavator-20 ton STANDARD FEATURES: 3 over 4 tine design, four rotation drive motors with pinion support and guard package, side heel arms for log handling, built in cylinder covers with 3.50 x 14.00 cylinders, machine adapter with pins 80mm, max tine opening between tips: 85.6 inches / 2.17m, material diameter (min rating): 4 inches / 101mm. Weight: 4100 lbs |

| DX-GL-FYHD-360-HX-25T

Grapple-Forestry Heavy Duty-360 degrees rotation-Hydraulic Excavator-25 ton STANDARD FEATURES: 3 over 4 tine design, four rotation drive motors with pinion support and guard package, side heel arms for log handling, built in cylinder covers with 3.50 x 14.00 cylinders, machine adapter with pins 80 or 90mm, max tine opening between tips: 85.6 inches / 2.17, material diameter (min rating): 4 inches / 101mm. Weight: 4200 lbs |

| Design and specifications are subject to change without notice. Please contact Dymax sales for custom solutions: 1-800-530-5407. |

HYDRAULIC REQUIREMENTS

| Your machine will require (1x) circuits for operation of the grapple (open and close.) It will require installation of the cable kit.

CIRCUIT 1-Grapple CIRCUIT2 – Rotator |

| NOT SUPPLIED: Not provided with jumper hose lines to the machine auxiliary lines. |