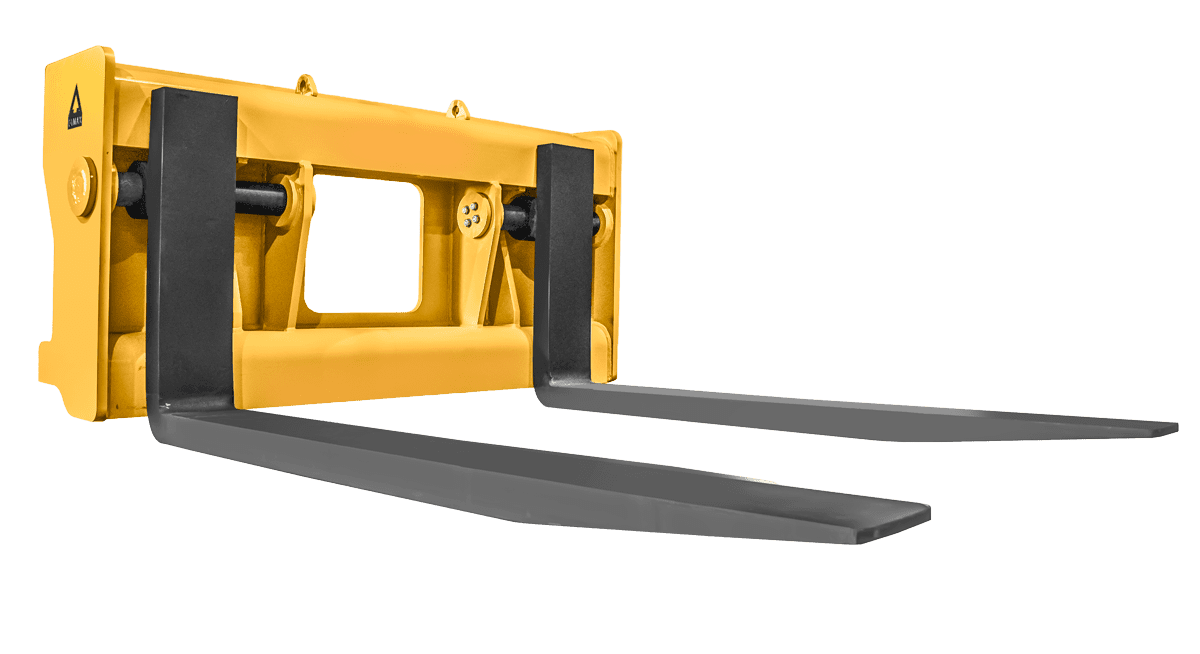

Block Handling Loader Forks

Whether you’re prying at the wall face or moving stone slabs, Dymax Block Handling Forks help increase productivity. Forged, heat-treated tines provide substantially greater strength and durability than conventionally manufactured tines.

Built for years of productive use, these forks are backed by the best service in the industry. They’re ideally suited for handling blocks of stone in quarry and mining applications.

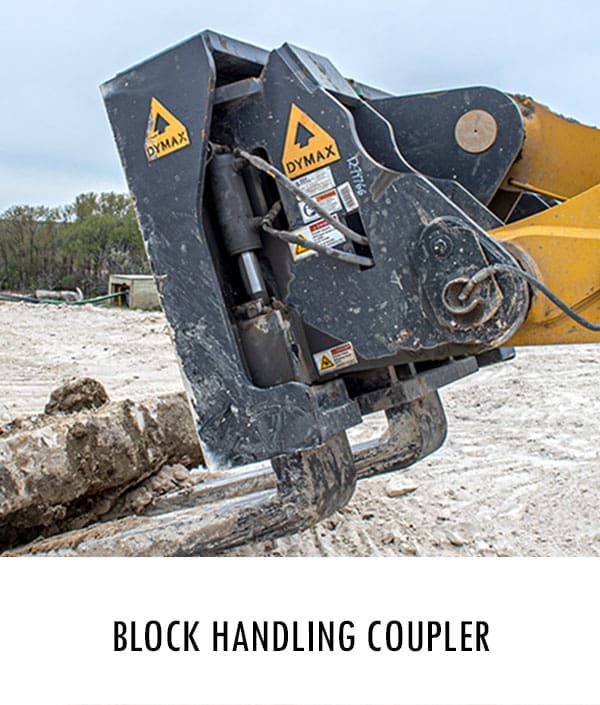

For maximum performance, pair your fork with a Dymax Block Handling Coupler. The wedgelock design provides positive lock and minimal breakout force loss, maximizing operators’ ability to handle large block stones and quarry slabs.