Model

Description

Weight |

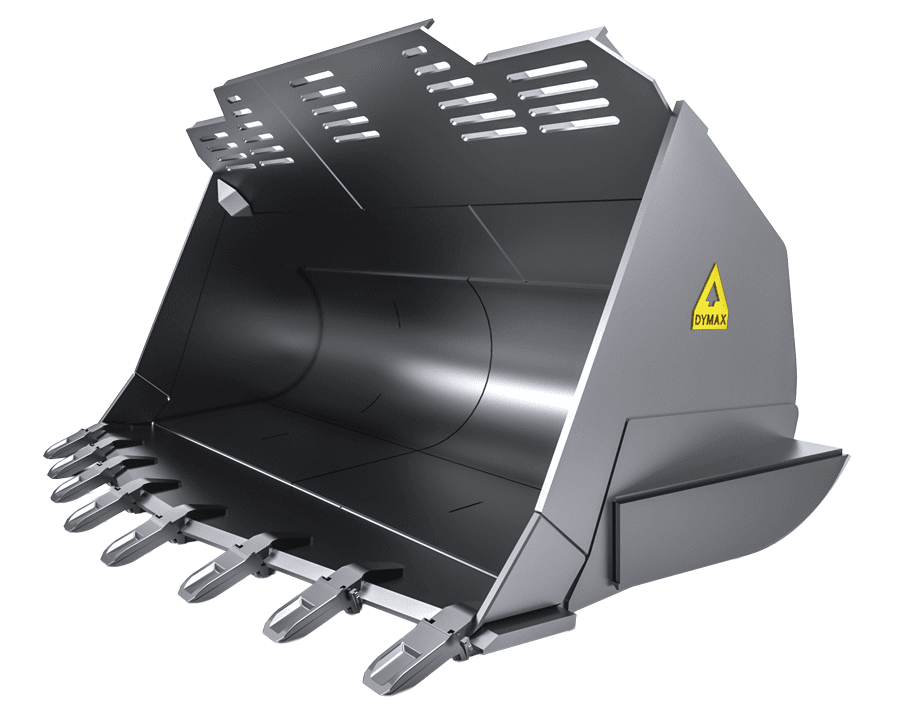

| DX-BK-SPDRK-4.50cyd-WL-80

Bucket-Spade Nose Rock-4.50 cubic yard capacity (SAE Heap Rating)-Wheel Loader-Class 80

STANDARD FEATURES:

– Spade nose cutting edge with replaceable bolt-on cutting edges

– Solid T1 steel moldboard (non-lined)

– Solid T1 lower corner with upper side cutter

– Wedge floor construction

– Rear bottom T1 wear plates

– Sideplate exterior wear plates

– Rear bottom bolt on wear pads

WIDTH: 128 inches

WEIGHT: 5850 lbs |

| DX-BK-SPDRK-5.00cyd-WL-80

Bucket-Spade Nose Rock-5.00 cubic yard capacity (SAE Heap Rating)-Wheel Loader-Class 80

STANDARD FEATURES:

– Spade nose cutting edge with replaceable bolt-on cutting edges

– Solid T1 steel moldboard (non-lined)

– Solid T1 lower corner with upper side cutter

– Wedge floor construction

– Rear bottom T1 wear plates

– Sideplate exterior wear plates

– Rear bottom bolt-on wear pads

WIDTH: 128 inches

WEIGHT: 6250 lbs |

| DX-BK-SPDRK-6.00cyd-WL-90

Bucket-Spade Nose Rock-6.00 cubic yard capacity (SAE Heap Rating)-Wheel Loader-Class 90

STANDARD FEATURES:

– Spade nose cutting edge with replaceable bolt-on cutting edges

– High-strength T1 moldboard group

– Replaceable lower side bar protection

– High-Strength T1 and AR400 wear plates

– Rock rack installed on top of moldboard

WEIGHT: 8200 lbs |

| DX-BK-SPDRK-6.50cyd-WL-90

Bucket-Spade Nose Rock-6.50 cubic yard capacity (SAE Heap Rating)-Wheel Loader-Class 90

STANDARD FEATURES:

– 6.50yd capacity spade nose edge 2-inch lip

– Standard T1 1/2-inch moldboard group (no liner)

– AR400 T1 side wear plates

– Side rock wing deflectors

– 8x adapters and tips

– 7x bolt-on-edge segments

– 4x side bar protectors

– 2x bolt-on rear wear plates

WIDTH: 145 inches

WEIGHT: 9200 lbs |

| DX-BK-SPDRK-6.75cyd-WL-100

Bucket-Spade Nose Rock-6.75 cubic yard capacity (SAE Heap Rating)-Wheel Loader-Class 100

STANDARD FEATURES:

– T1 6in hooks set up with bushings / 53.56 hook spacing

– 3in lock pin ears

– 6.75yd capacity spade nose edge 2in lip

– Standard T1 1/2in moldboard group (no liner)

– AR400 T1 side wear plates

– Side rock wing deflectors

– 8x K110 adapters and tips

– 7x bolt-on edge segments

– 4x Cat side bar protectors

– 2x Cat bolt-on rear wear plates

WIDTH: 145 inches

WEIGHT: 9500 lbs |

| DX-BK-SPDRK-7.00cyd-WL-90

Bucket-Spade Nose Rock-7.00 cubic yard capacity (SAE Heap Rating)-Wheel Loader-Class 90

STANDARD FEATURES:

– 2.00 inch thick spade nose cutting edge

– High-strength 0.50-inch-thick T1 moldboard group

– Wedge floor design

– Replaceable lower side bar protection

– High-strength T1 and AR400 wear plates

– Rock rack installed on top of moldboard

WEIGHT: 9000 lbs |

| DX-BK-SPDRK-7.50cyd-WL-90

Bucket-Spade Nose Rock-7.50 cubic yard capacity (SAE Heap Rating)-Wheel Loader-Class 90

STANDARD FEATURES:

– Spade nose cutting edge with replaceable bolt-on cutting edges

– High-strength T1 moldboard group

– Replaceable lower side bar protection

– High-strength T1 and AR400 wear plates

– Rock rack installed on top of moldboard

WEIGHT: 9400 lbs |

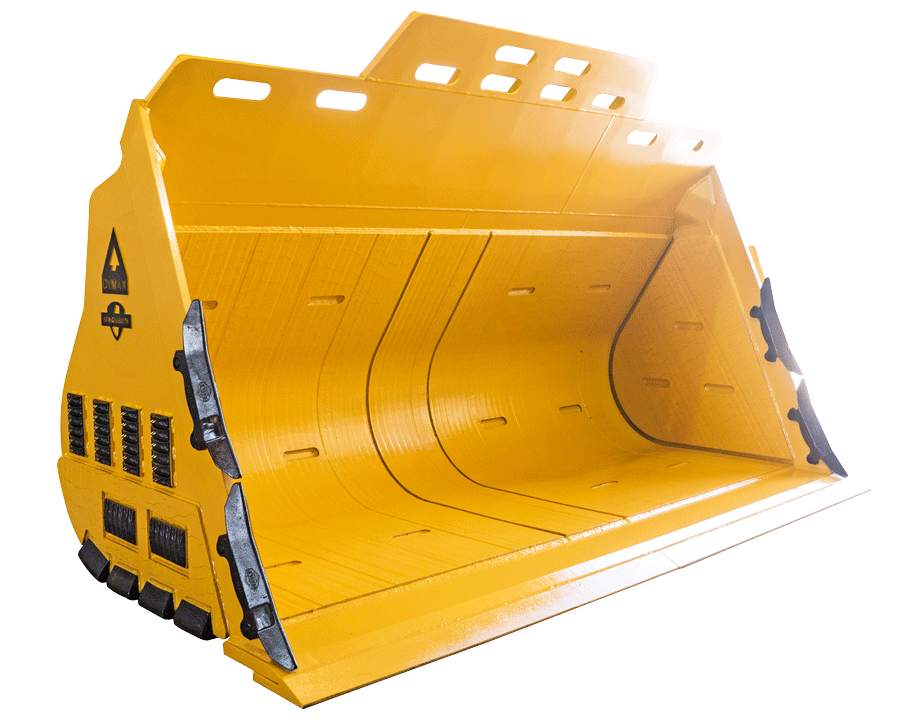

| DX-BK-SPDRK-9.00CAT-WL-100

Bucket-Spade Nose Rock-9.00 cubic yard capacity CAT 457 1941 EDGE ASSY-Wheel Loader-Class 100

STANDARD FEATURES:

– T1 moldboard group

– AR400 0.38 inch liner group

– Tire guards on exterior side plates

– AR400 bottom wear plates

– CAT Edge Assembly (4571941) fitted with ADVANSYS 130 Adapters and Tips (GP Tip – 381-4094)

– Bolt-on edge segments – 7x CAT standard edge segments installed

– Includes 4x side bar protectors (2 per side)

– 7 degree floor slope – wedge floor design

EDGE WIDTH: 158.5 inches

OVERALL WIDTH OUTSIDE TIRE GUARDS: 164 inches

WEIGHT: 12500 |

| DX-BK-SPDRK-9.50cyd-WL-100

Bucket-Spade Nose Rock-9.50 cubic yard capacity (SAE Heap Rating)-Wheel Loader-Class 100

STANDARD FEATURES:

– Spade nose cutting edge with replaceable bolt-on cutting edges

– High-strength T1 moldboard group

– Replaceable lower side bar protection

– High-strength T1 and AR400 wear plates

– Rock rack installed on top of moldboard

WEIGHT: 13,000 lbs |

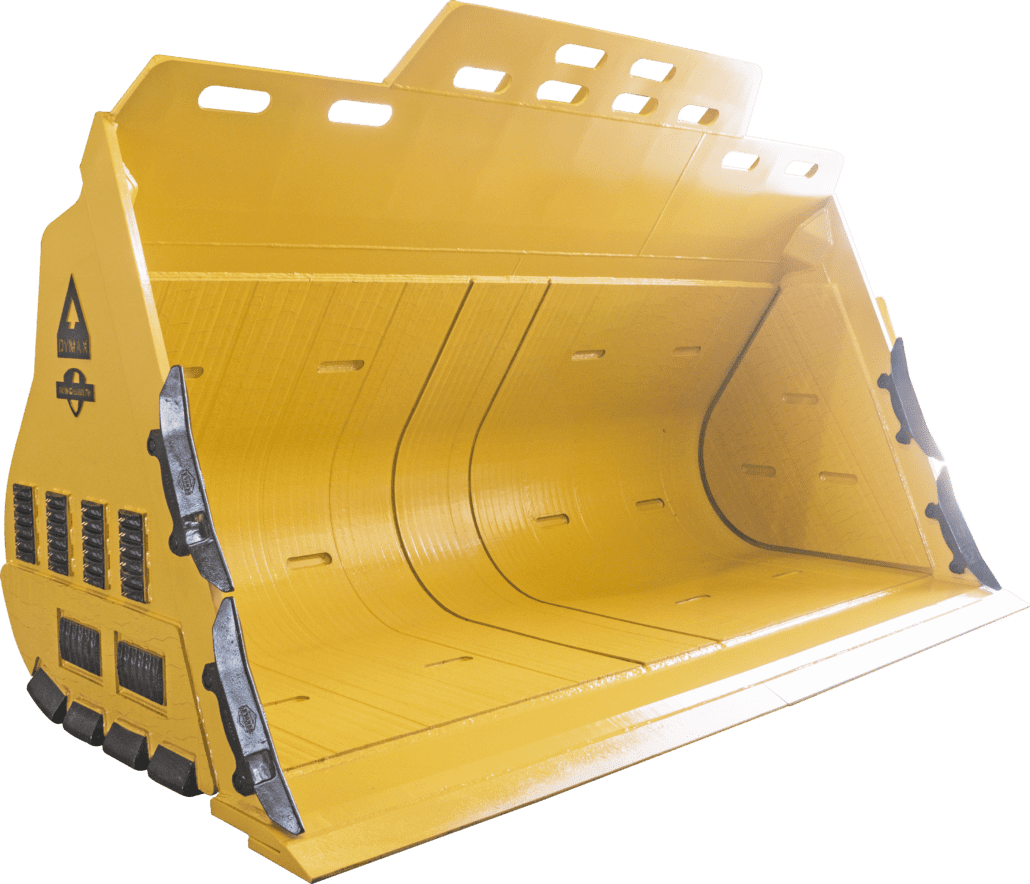

| DX-BK-SPDRK-10.00CAT-WL-100

Bucket-Spade Nose Rock-10.00 cubic yard capacity CAT 457 1941 EDGE ASSY-Wheel Loader-Class 100

STANDARD FEATURES:

– T1 moldboard group

– AR400 0.38 inch liner group

– Tire guards on exterior side plates

– AR400 bottom wear plates

– CAT Edge Assembly (4571941) fitted with ADVANSYS 130 Adapters and Tips (GP Tip – 381-4094)

– Bolt-on edge segments – 7x CAT standard edge segments installed

– Includes 4x side bar protectors (2 per side)

– 7 degree floor slope – wedge floor design

EDGE WIDTH: 158.5 inches

OVERALL WIDTH OUTSIDE TIRE GUARDS: 164 inches

WEIGHT: 13,500 lbs |

| DX-BK-SPDRK-10.00JD550-WL-100

Bucket-Spade Nose Rock-10.00 cubic yard capacity with Deere T550 tooth system-Wheel Loader-Class 100

STANDARD FEATURES:

– 0.63 A572 standard moldboard group with full liner package (AR400 3/8″ inch thick)

– Sidebars – 1.25in thick A514 with lower corner weld-on side shroud

– Wedge floor design

– Tire guards on outside side plates built with T1 steel

– Rear bolt-on wear pads (DY29157x2) with T1 bottom wear plates

– Horizontal slotted upper moldboard group

EDGE ARRANGEMENT

– Heavy Duty Plate Lip configured with Deere teeth and segments

– Deere T550 LH, RH and Center adapters for spade nose (8 total) – (2) TK550C250, (3) TK550R250 AND (3) TK550L250

– Deere T550 Replaceable Tips (8 total) (TK550LDH)

– Deere Segments: 7x Deere bolt-on Shrouds between teeth (AT404440 Kit group)

WEIGHT: 13,450 lbs |

| DX-BK-SPDRK-10.00LMSTR-WL-100

Bucket-Spade Nose Rock-10.00 cubic yard capacity Loadmaster Lip-Wheel Loader-Class 100

STANDARD FEATURES:

– T1 moldboard group

– AR400 .38in thick liner group

– Tire guards on outside side plates

– AR400 bottom wear plates

– Esco Loadmaster Lip 151.2 inches wide

– Lip Shrouds – 7x Top Lok Lip Shrouds between teeth

– Adapters – 8x Ultralok U45 with U45A tips

– 2.00in edge thickness

– 7 degree floor slope wedge floor

WIDTH: 164 inches

WEIGHT: 13,450 lbs |

| DX-BK-SPDRK-11.00LMSTR-WL-100

Bucket-Spade Nose Rock-11.00 cubic yard capacity Loadmaster Lip-Wheel Loader-Class 100

STANDARD FEATURES:

– T1 moldboard group

– AR400 0.38in liner group

– Tire guards on exterior side plates

– AR400 bottom wear plates

– Esco Loadmaster Lip 151.2 inches wide

– Lip Shrouds – 7x toplok lip shrouds between teeth

– Adapters – 8x Ultralok U45 with U45A Tips

– 2 in edge thickness

– 7 degree floor slope – wedge floor design

WIDTH: 164 inches

WEIGHT: 14,100 lbs |

| DX-BK-SPDRK-12.00LMSTR-WL-100

Bucket-Spade Nose Rock-12.00 cubic yard capacity Loadmaster Lip-Wheel Loader-Class 100

STANDARD FEATURES:

– T1 moldboard group

– AR400 0.38 inch liner group

– Tire guards on exterior side plates

– AR400 bottom wear plates

– Esco Loadmaster Lip 151.2 inches wide

– Lip Shrouds – 7x toplok lip shrouds between teeth

– Adapters – 8x Ultralok U45 with U45A Tips

– 2.00in edge thickness

– 7 degree floor slope – wedge floor design

OVERALL WIDTH OUTSIDE DEFLECTORS: 164 inches

WEIGHT: 14,800 lbs |

| DX-BK-SPDRK-12.00cyd-WL-110

Bucket-Spade Nose Rock-12.00 cubic yard capacity (SAE Heap Rating)-Wheel Loader-Class 110

STANDARD FEATURES:

Suited FOR CATERPILLAR 990H or KOMATSU WA700 WHEEL LOADER

– Spade nose cutting edge

– Wedge floor construction

– Includes weld-on adapters and tips with edge segments

– High-strength T1 steel moldboard group

– AR400 bucket moldboard liner package

– Replaceable side bar protectors installed

– Kwik Lock wear pads installed on underside of bucket (6x total)

– Rock rack installed on top of moldboard

– Tire guards

BUCKET WIDTH: approx. 181-184 inches, subject to tooth layout / type.

OVERALL WIDTH: 192 inches outside of rock tire guards on side plates

MATERIAL WEIGHT DENSITY: approx. 2800-2980 lbs/yd

BUCKET WEIGHT: 18,000 lbs |

| DX-BK-SPDRK-14.50cydGRANITE-WL-120

Bucket-Spade Nose Rock-14.50 cubic yard capacity GRANITE (SAE Heap Rating)-Wheel Loader-Class 120

STANDARD FEATURES:

– Spade nose cutting edge with 8x K170 adapters and Abrasion tips (232-2178) with retainer (247-7241 SPEC STYLE)

– 7x Bolt-on half-arrow-style segments with bolt-on top guard plates (345-5470-345-5471 & 5472)

– High strength T1 moldboard with wedge floor design

– Includes full liner package (GRANITE) type for severe abrasion. Features 2 horizontal wear bars, full side plate coverage, multi-section liners on aux spill plate and main moldboard liners set up with plug welds.

– 3 rear bolt-on CAT edge wear plates installed (345-6752)

– MAWPS replaceable wear blocks/pads installed on the underside wedge floor area (total 24 pieces)

– Side weld-on CAT heel shrouds installed on the underside radius of the side plates and bucket bottom. (6 total / 3 per side)

– Dual pin-on CAT style side bar protectors (2 per side) covering 75% of the lower side bar

– Exterior rock/tire guards installed on outer side plates with 2″ thick bolt-on wear pads (not MAWPS)

EDGE WIDTH: 196 inches

OVERALL WIDTH WITH ROCK/TIRE GUARDS: approx. 220 inches outside to outside.

WEIGHT: 34,000 lbs |

| DX-BK-SPDRK-16.00cyd-WL-120

Bucket-Spade Nose Rock-16.00 cubic yard capacity (SAE Heap Rating)-Wheel Loader-Class 120

STANDARD FEATURES:

– Spade nose cutting edge with replaceable bolt-on cutting edges

– High-strength T1 moldboard group

– Replaceable lower side bar protection

– High-strength T1 and AR400 wear plates

– Rock rack installed on top of moldboard

WEIGHT: 25,600 lbs |

| DX-BK-SPDRK-16.00cydCAT-WL-120

Bucket-Spade Nose Rock-16.00 cubic yard capacity with CAT G.E.T.(SAE Heap Rating)-Wheel Loader-Class 120

STANDARD FEATURES:

– Spade nose cutting edge with replaceable bolt-on cutting edges

Edge Assy styling – 491-9811

GET: K170 Advansys adapters and tips

(2) 368-3825 center

(3) 368-3826 right hand

(3) 368-3827 left hand

(7) bolt on edge HALF ARROW segments installed

– 190.00 inches wide

– Bottom weld-on rear wear plates

– (24) CAT MAWPS replaceable wear pads installed on bottom of bucket wear plates as full wear pad system. (12 PER SIDE) ON REAR (626-9962 CAT KIT #)

– 3/4″ T1 standard moldboard group with 5/8″ AR400 wear 3-section wear liner plate

– 4x replaceable side bar protectors (1U-0740 DY72636)

– Rock rack installed on top of moldboard

– Exterior tire guards on outside side plates

WEIGHT: 25,600 lbs |

| DX-BK-SPDRK-18.00cyd-WL-120

Bucket-Spade Nose Rock-18.00 cubic yard capacity (SAE Heap Rating)-Wheel Loader-Class 120

STANDARD FEATURES:

– Spade nose cutting edge with replaceable bolt-on cutting edges

– High-strength T1 moldboard group

– Replaceable lower side bar protection

– High-strength T1 and AR400 wear plates

– Rock rack installed on top of moldboard

WEIGHT: 28,000 lbs |

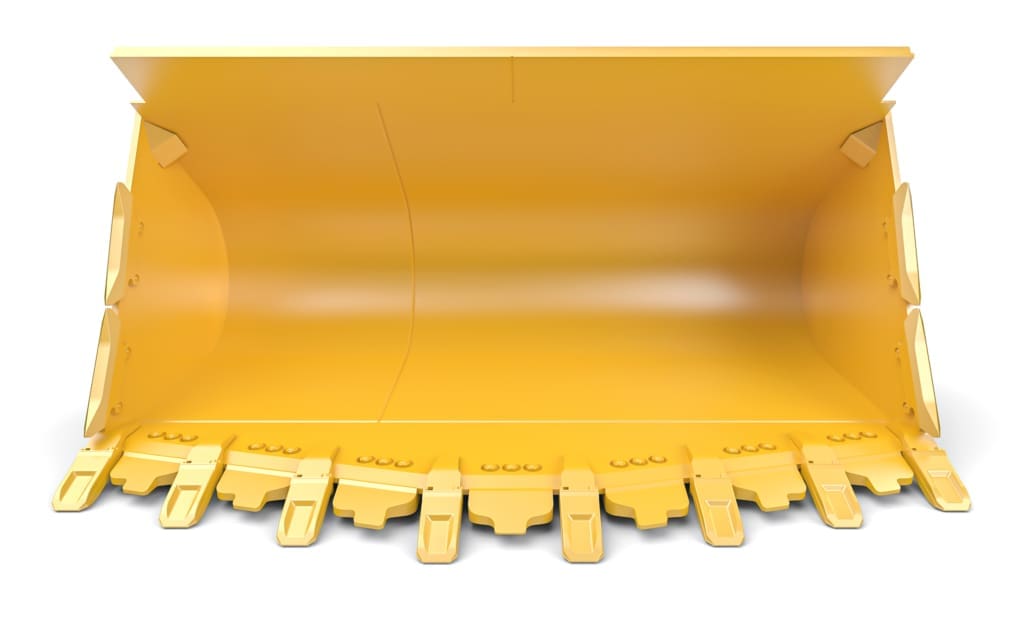

| DX-BK-SPDRKO-22.50cyd-WL-125

Bucket-Spade Nose OVERBURDEN-22.50 cubic yard capacity (SAE Heap Rating)-Wheel Loader-Class 125

STANDARD FEATURES:

– Edge width: 18 feet 8 inches wide / 226.38 inch lip width

– Outside width over tire guards: approximately 240 inches

– Edge: 90mm Stepped Spade Nose (CAT #573-9464 / Dymax # DY203537)

– GET: (9) Cat Advansys 170 adapters and (9) replaceable teeth

– GET2: (8) Cat bolt-on edge segments

– GET3: (8) Cat top edge wear plates

– Moldboard Group: T1 3/4 thick moldboard with 1/2″ AR400 lower plug-welded wear liner covering floor and back radius

– Replaceable Cat Style lower and upper side bar protectors DY72636 Cat Style 4 total, 2 per side DY72637 Pins 8x, DY54934 Retainers 8x

– High-strength T1 and AR400 wear plates

– CAT MAWPS wear pads on the underside. 18 total – 9 per side, DY203550_1380050 – Wear Base, DY20355_138-0050 – Wear Pad

– Rock rack installed on top of moldboard – reinforced Letourneau-style design

– Includes rock/tire guards on exterior side plates

WEIGHT: 34,000 lbs |