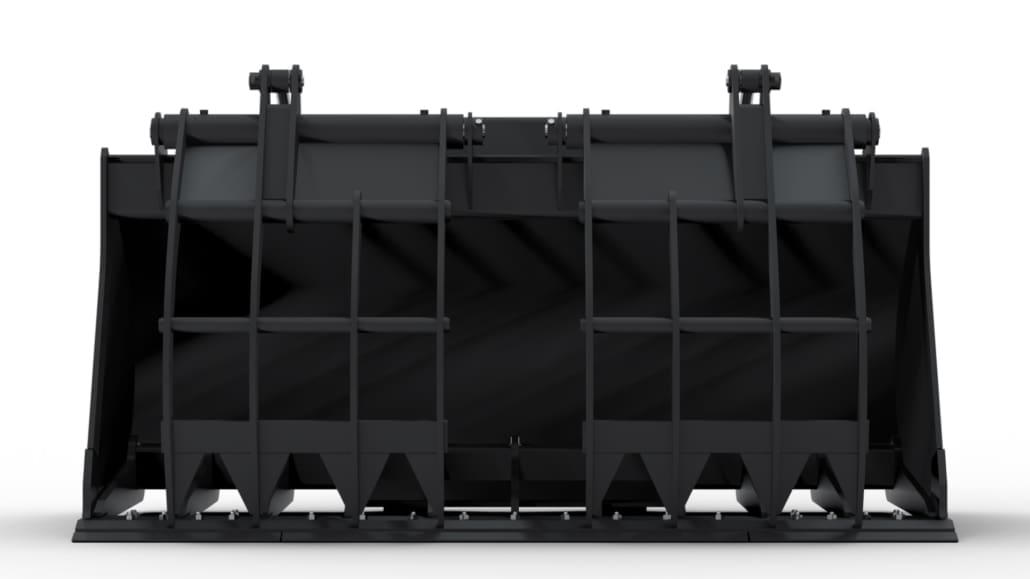

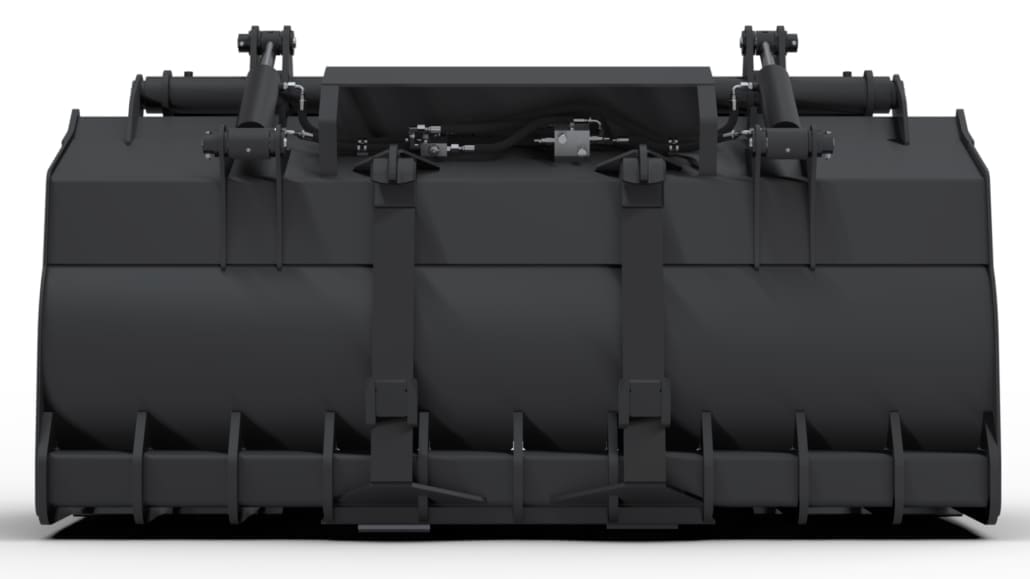

SKELETON FLOOR GRAPPLE BUCKET

For Wheel Loaders & Backhoe loaders

Built for heavy-duty sorting and handling, the Dymax Skeleton Floor Grapple Bucket is designed to separate materials efficiently while keeping larger loads secure. The T1 steel tine floor lets finer material fall through, reducing unnecessary weight. With durable side plates, bolt-on cutting edges and reinforced heel wear plates, this bucket is ideal for demanding applications such as land clearing, demolition and debris handling.

KEY FEATURES

- T1 steel constructed tine floor allows unwanted material to fall through. Wheel loader models: 10 inch tine spacing. Backhoe loader models: 6 inch tine spacing.

- Full side plates and replaceable bolt-on cutting edges.

- Heavy duty cylinders, pins and bushings.

- Dual clamps with relief and counterbalance valves.

- T1 steel bottom heel wear plates on wheel loader models.

- Available in widths ranging from 96-120 inches, subject to machine size and capacity.

SPECIFICATIONS

| Model Code Description Width Weight |

|||

| DX-BK-GLSK-1.25cyd-BL-10

Bucket-Grapple with Skeletal Floor-1.25 cyd capacity-Backhoe Loader-Class 10 STANDARD FEATURES: Full side plates like conventional bucket, replaceable 2 piece 0.75×8.0 bolt-on cutting edge, HD cylinders, pins and bushings, dual clamps with relief and counterbalance valves, skeleton tine construction, 6 inch spacing A572 steel constructed tine floor allowing for material to fall through. Width Range (subject to machine): 96 inches WEIGHT: 1950 lbs |

|||

| DX-BK-GLSK-2.50cyd-WL-40

Bucket-Grapple with Skeletal Floor-2.50 cyd capacity-Wheel Loader-Class 40 STANDARD FEATURES: Full side plates like conventional bucket, replaceable bolt-on cutting edges, HD cylinders, pins and bushings, dual clamps with relief and counterbalance valves, T1 bottom heel wear plates, 10 inch spacing T1 steel constructed tine floor allowing for material to fall through. Width Range (subject to machine): 100-102 inches WEIGHT: 4000 lbs |

|||

| DX-BK-GLSK-3.00cyd-WL-50

Bucket-Grapple with Skeletal Floor-3.00 cyd capacity-Wheel Loader-Class 50 STANDARD FEATURES: Full side plates like conventional bucket, replaceable OEM pattern bolt-on cutting edges, HD cylinders, pins and bushings, dual clamps with relief and counterbalance valves, T1 bottom heel wear plates, 10 inch spacing T1 steel constructed tine floor allowing for material to fall through. Width Range (subject to machine): 100-102 inches WEIGHT: 4800 lbs |

|||

| DX-BK-GLSK-4.00cyd-WL-60

Bucket-Grapple with Skeletal Floor-4.00 cyd capacity-Wheel Loader-Class 60 STANDARD FEATURES: Includes set of bolt-on side plates, replaceable bolt-on cutting edges, HD cylinders, pins and bushings, dual clamps with relief and counterbalance valves, T1 bottom heel wear plates, 10 inch spacing T1 steel constructed tine floor allowing for material to fall through. Width Range (subject to machine): 113-120 inches WEIGHT: 5250 lbs |

|||

| DX-BK-GLSK-4.50cyd-WL-60

Bucket-Grapple with Skeletal Floor-4.50 cyd capacity-Wheel Loader-Class 60 STANDARD FEATURES: Includes set of bolt-on side plates, replaceable bolt-on cutting edges, HD cylinders, pins and bushings, dual clamps with relief and counterbalance valves, T1 bottom heel wear plates, 10 inch spacing T1 steel constructed tine floor allowing for material to fall through. Width Range (subject to machine): 113-120 inches WEIGHT: 5150 lbs |

|||

| DX-BK-GLSK-5.00cyd-WL-60

Bucket-Grapple with Skeletal Floor-5.00 cyd capacity-Wheel Loader-Class 60 STANDARD FEATURES: Includes set of bolt-on side plates, replaceable bolt-on cutting edges, HD cylinders, pins and bushings, dual clamps with relief and counterbalance valves, T1 bottom heel wear plates, 10 inch spacing T1 steel constructed tine floor allowing for material to fall through. Width Range (subject to machine): 113-120 inches WEIGHT: 5450 lbs |

|||

| Design and specifications are subject to change without notice. Please contact Dymax sales for custom solutions 1-800-530-5407. |

HYDRAULIC REQUIREMENTS

| Your machine will require 3rd function auxiliary lines.

CIRCUIT 1 – Clamp Operation Type – Two way Flow/Pressure – GPM (min/max) 15-25, PSI (max) 3,000 |

|||

| NOT SUPPLIED: Does not include jumper hoses to machine lines or quick disconnects. |